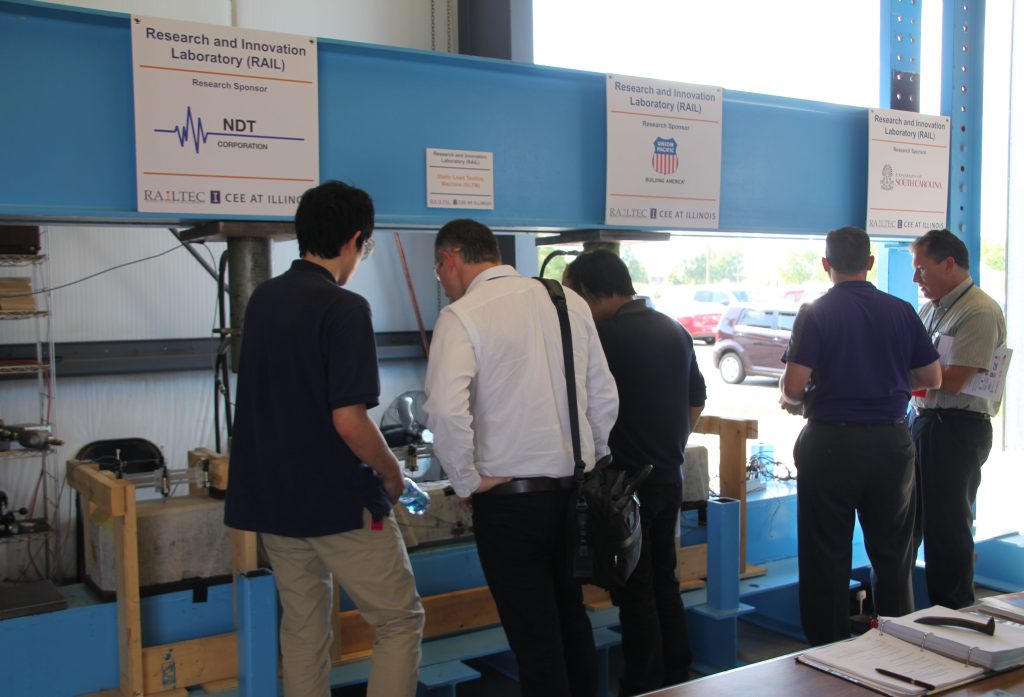

RAIL currently houses multiple testing frames which provide the ability to conduct a variety of industry standard and custom experiments on railway infrastructure and mechanical components including crossties and fastening systems. RAIL provides researchers with the necessary tools to study various infrastructure components at the material, component, and system levels.

The cornerstone of RAIL is the track loading system (TLS) which provides researchers the ability to perform static and dynamic experimentation on railway superstructure and rolling stock mechanical components and full-depth track substructures. The data gathered from TLS experimentation also provides researchers the ability to develop new and validate previous railway infrastructure models.

Track Loading System (TLS)

- Operational since Spring 2014

- Experimental capabilities

- Two 55,000 lb (222kN) actuators and one 100,000 lb (444kN) hydraulic cylinder

- One 100,000 lb hydraulic cylinder

- Full-depth track substructure for representative support conditions

- Functionality

- Ability to construct a full-depth track substructure for representative support conditions

- Eleven (11) crossties for representative end-effects

- Loading via wheelset for representative loading conditions

- Ability to change the L/V and magnitude of loads applied

- Ability to answer hypothesis based questions pertaining to infrastructure and substructure

- Uses instrumented wheel set (IWS) to accurately characterize wheel rail interface forces

- Current/Recent Application(s)

- Investigation into vertical and lateral fastening system load path

- Study effect of crosstie support conditions on concrete crosstie bending moments

- Investigation into benefits of new crosstie designs

Pulsating Load Testing Machine (PLTM)

- Owned by Amsted RPS

- Maintained and managed by UIUC since Spring 2010

- Experimental Capabilities

- One 55,000 lb (222kN) and one 35,000 lb (156kN) actuator

- Functionality

- Ability to simulate various L/V force ratios (e.g. track conditions)

- Adaptability for other support and service conditions (e.g. ballast box and environmental chamber)

- Current/Recent Application(s)

- Can be used to perform AREMA Test 6 (Wear and Abrasion)

- Investigation into crushing rail seat deterioration (RSD) mechanism

Static Tie Tester (STT)

- Owned by RailTEC/UIUC since Summer 2012

- Experimental Capabilities

- Two 95,000 lb (422 kN) hydraulic cylinders

- Functionality

- Ability to study the rail seat and rail pad compression

- Ability to simulate various support conditions (e.g. track conditions)

- Ability to study the flexural capacity of crossties

- Current/Recent Application(s)

- Execution of composite and concrete crosstie bending moment tests

- Investigation into moment capacity and effect of crosstie length

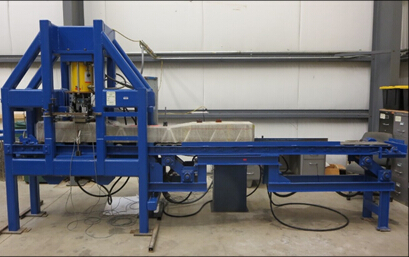

Static Load Testing Machine (SLTM)

- Experimental Capabilities

- Two 100,000 lb (444kN) hydraulic cylinders

- Application

- Used to run component level experiments on crossties

Large Scale Test Frame (LSTF)

- Experimental Capabilities

- Flexible; currently configured with 100,000 lb (444kN) & 35,000 lb (156kN) hydraulic actuators

- Application

- Used to run rail infrastructure component level experiments (crossties, joint bars, etc.)

Control Platform

- Current Applications

- All servo-hydraulic equipment at RAIL is operated from the control platform

Test Track Section